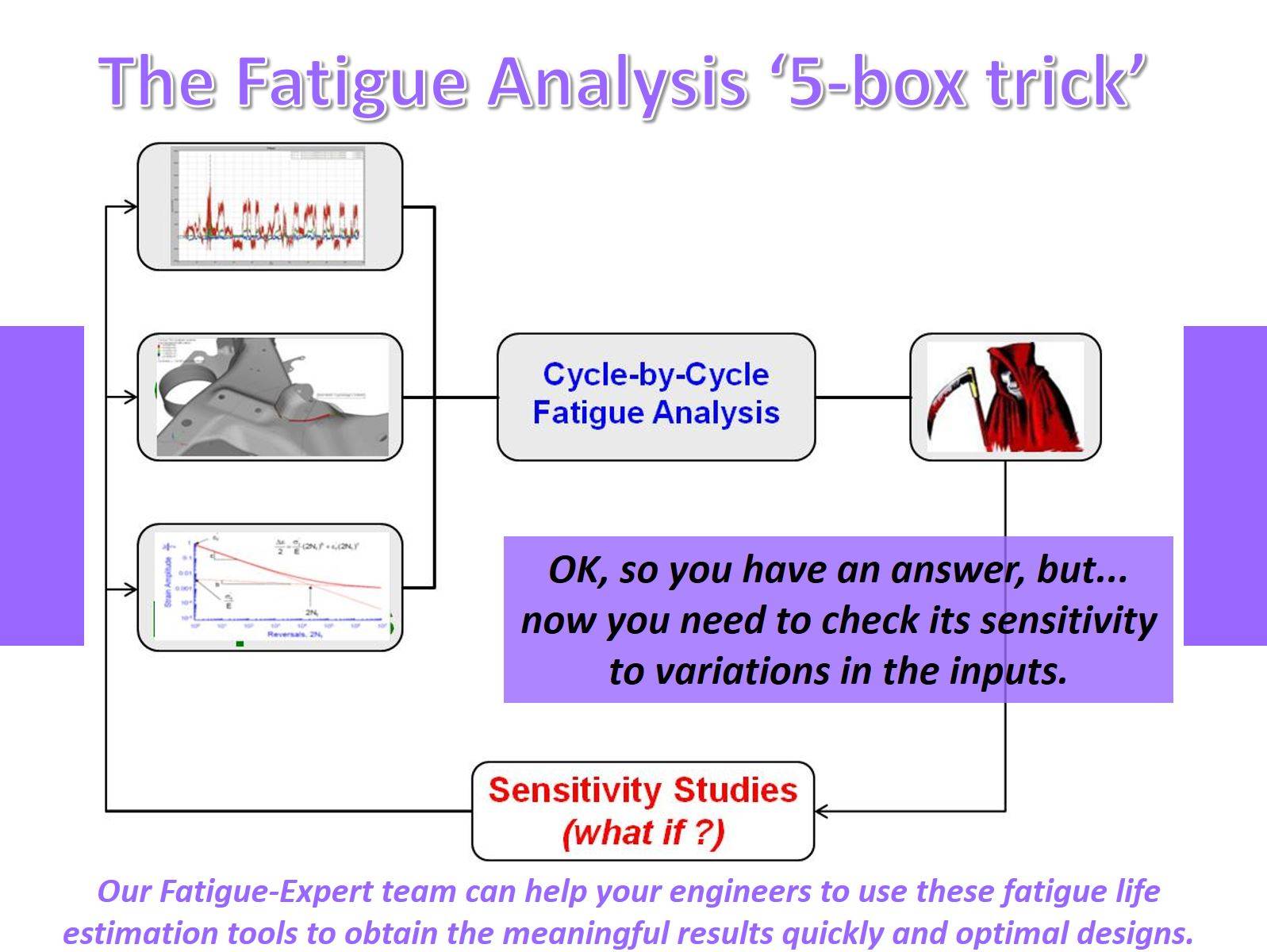

Who are Fatigue-Expert

and how can we help your

Product Development?

We are a group of consultants with a broad expertise in fatigue, durability, crack growth, fracture mechanics, materials behaviour, loads, stress analysis and failure investigations. This knowledge comes from over 35 years practice in these technologies both from a test and CAE perspective working with and for some of the leading global fatigue hardware and software technology companies. Our durability consultancy group came from the Alpha and Omega Business Consultancy organisation, hence the AΩBC reference in our logo.

Our broad experience has been developed whilst working for a wide range of industries including:

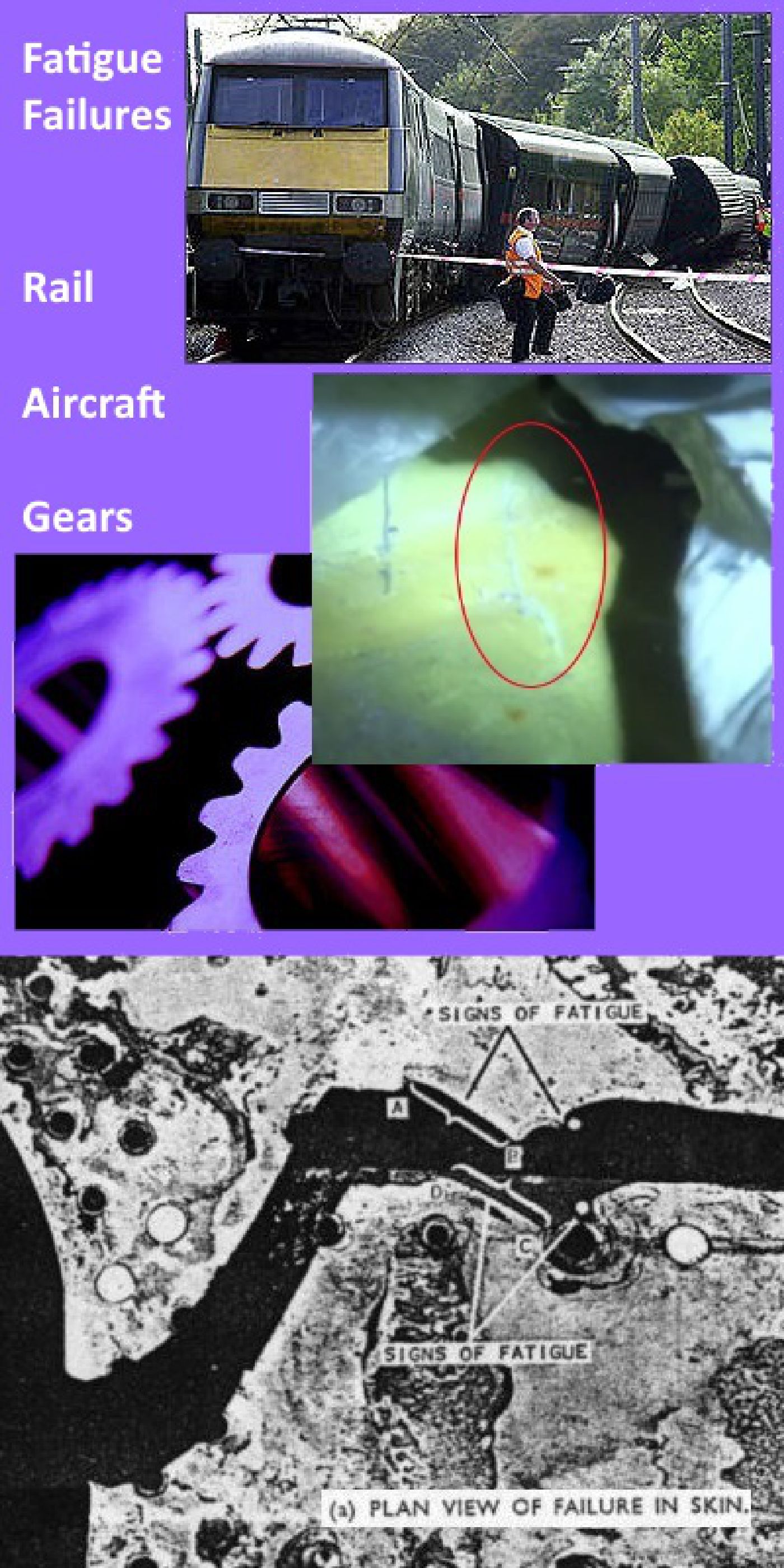

■ automotive,railway, trucks and other ground vehicles

■ aircraft and aerospace

■ oil and gas, and offshore renewable energy plant

■ general machinery such as packaging machines,

domestic appliances, and recreational products

■ ship and marine structures

■ electronics, packaging and machines

A Thought ...

"Every stress analysis is really a fatigue analysis - the issue is just how many cycles!"

Maybe this is not always true but in our view the stressing is often not the end of the road for designers - the fatigue life is the critical issue.

Best practice for FE modelling for fatigue is vital ... and one of our key skills! Remember fatigue is about local stresses and strains but stress concentrations need to be considered and handled carefully.

The skills of our fatigue experts have been proven many times in solving fatigue problems, helping companies improve their products, getting machines back in service, including getting a rail network back up and running after a fatigue failure led to block in use of rolling stock until a safety case was proven!

Our unique service has established our place in this industry. This allows us to make a distinctive and substantial impact for our clients, delivering to them excellent value and delighting then in the process.

For more details and a confidential discussion, contact Fatigue-Expert today.

FOLLOW US